In this free 30-minute webinar on February 18th, we’ll walk through the latest updates that have been made in the new version of our Wood Framing and Metal Framing BIM Solutions for Revit.

The latest version of our timber and steel framing software incorporates several client requests. Among the new features that have been developed are: independent control of top and bottom cripples, ability to manipulate top and bottom plates in wall-to-wall connections, increased functionality for modifying sheathing and paneling, some dimensioning options, and more.

We relish the opportunity to improve our BIM tools to meet the needs of framing professionals the world over. It’s how we build BIM together.

The webinar will be held twice, so please register for the session that’s more convenient for you. Content will especially be of interest to designers of wood-framed buildings or light-gauge metal framed buildings, architects, engineers, BIM managers, and out-of-box Revit users.

In this webinar, you’ll see how to

- Replace missing families or types in the project

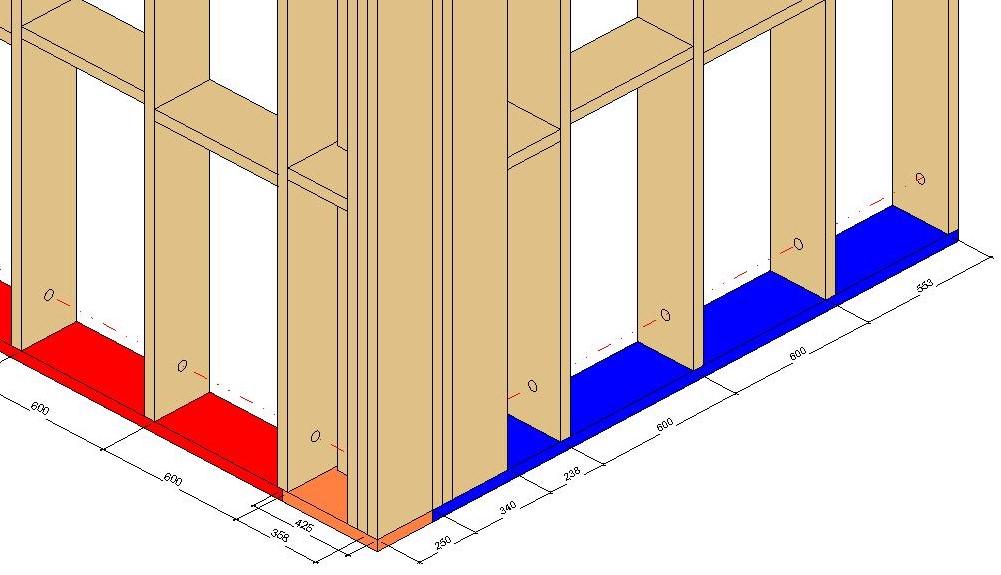

- Control Top and Bottom Cripples for Window, Door, and Opening separately

- Link database configurations together throughout all parts of your framing configurations

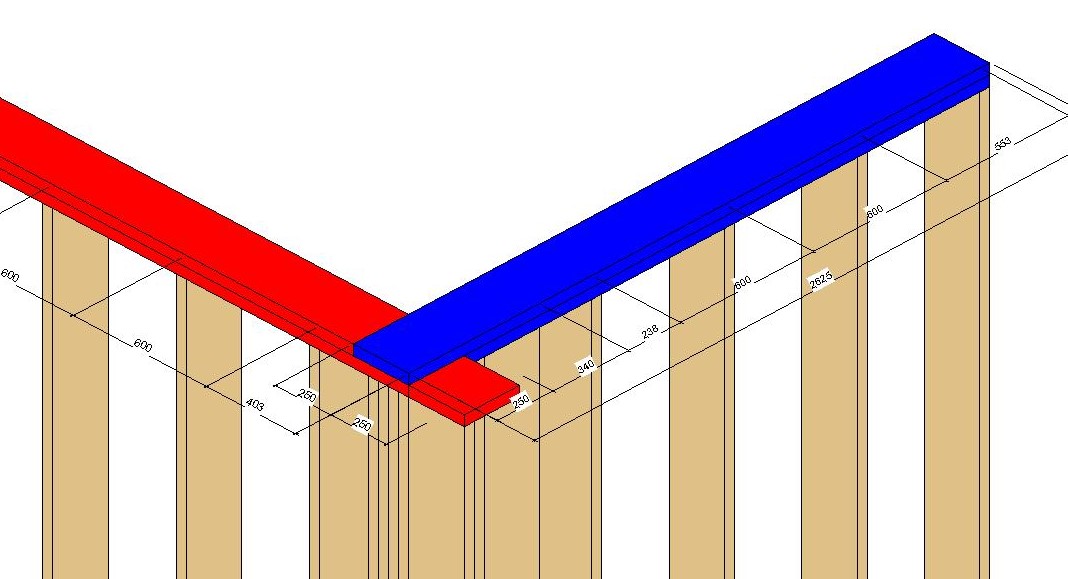

- Control top and bottom plates in L, End, V, and T wall connection types more efficiently

- Benefit from expanded Split Elements tool set

- Control Opening Configuration by the Family Type

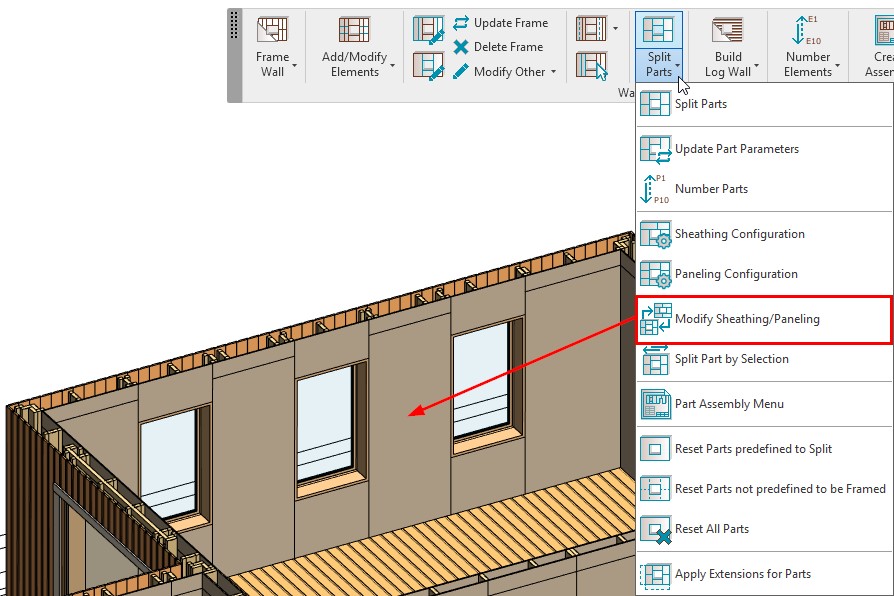

- Modify sheathing and paneling by choosing a different configuration

- Create or exclude parts with the ‘Frame Wall’ command

- Cut bottom plates with a void

- Add Studs in the center of the Wall automatically

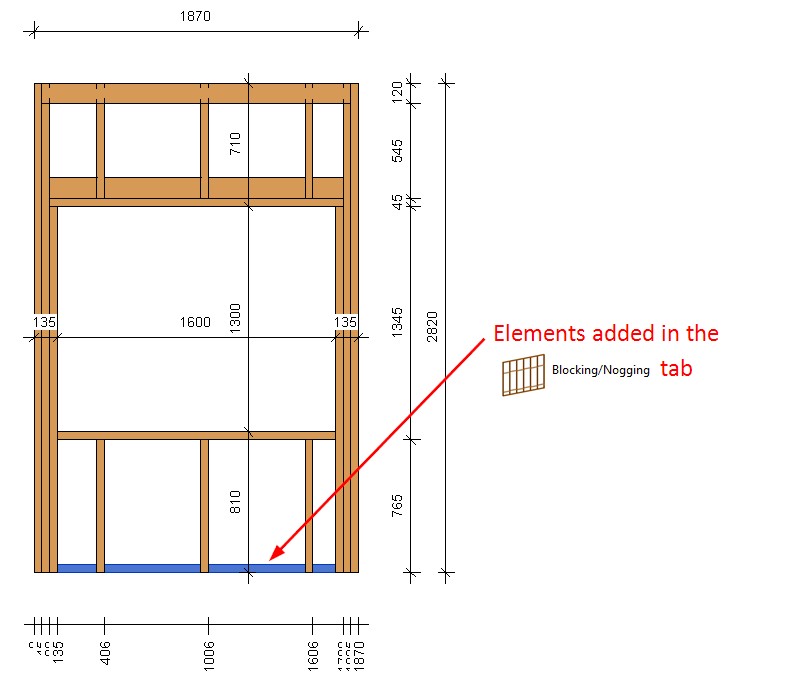

- Add Blocking/Nogging elements to a Preassembled Opening automatically

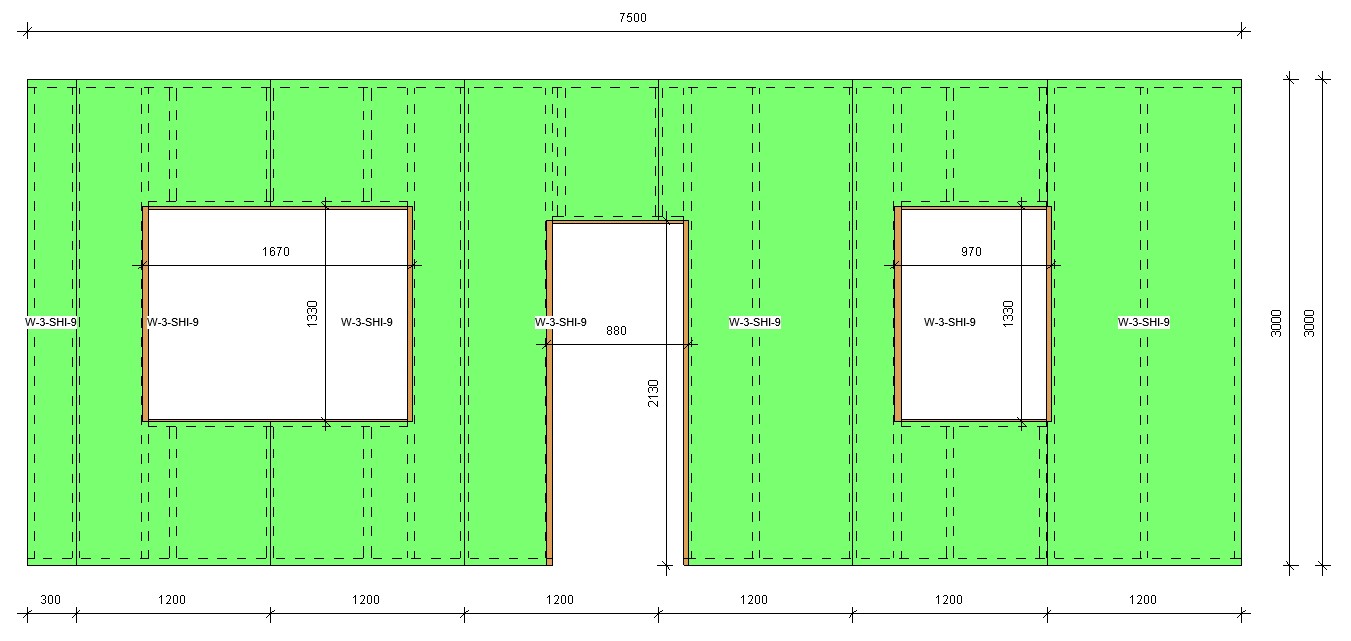

- Create dimensioning configurations in multiple dimensioning rule tabs for same-category elements

- Auto-dimension part openings

- Use material as a text note parameter

- Align view positions by views placed in the Sheet Template

Your host

Solutions

Our Wood Framing and Metal Framing BIM Solutions make your job in Autodesk Revit much simpler, much less stressful, and way faster. It’s easy to distribute hardware and fastener details, manage openings and connections, find clashes, and add, modify, or mark just the right elements or parameters en masse. Frames dynamically update and adapt if modifications are made, ensuring that shop drawings and cut lists are always accurate.

We hope to see you online!